Magnetic Flux Leakage Detector

Pipeline Magnetic Leakage Detector - Non destructive Testing Equipment Expert | Yaisu Intelligent

Technical principle:

Leakage magnetic detector establishes a closed magetic circuit by magnetizing the pipeline wall.

When there are defects such as corrosion and cracks on the pipeline wall, the distortion of magnetic field lines

produces a leakage magnetic field. The high-precision Hall sensor array captures the leakage magnetic field signal

and implements defect quantification analysis through a data processing system. This technology has low requirements

for pipeline cleanliness and is suitable for online inspection of oil/gas pipelines.

System composition and technology

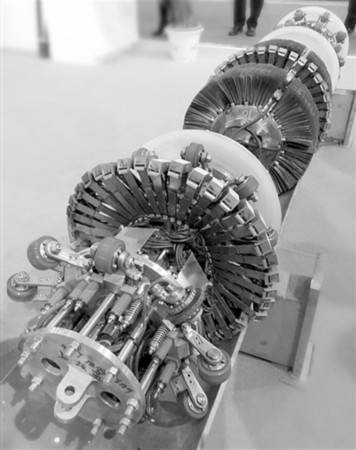

Magnetizing mechanism:

Permanent magnet/electromagnetic coil saturated magnetization tube wall (magnetic flux density ≥ 1.8T)

Four detector circular array design, electric telescopic rod adaptive adjustment of detection position

Sensing system:

18 sets of Hall probe arrays, with a circumferential spacing of ≤ 8mm and an axial sampling interval of 2mm

Anti lift off technology: Sensor height from pipe wall ≤ 2mm, signal attenuation rate<25%/mm

Drive and Safety

High pressure medium drive (0.45MPa water pressure propulsion), replacing vulnerable top rod structures

Dual redundant braking system+real-time health monitoring module.

Application areas:

Submarine pipelines, long-distance oil and gas pipelines, tank bottom plates

Get exclusive solution now: +86 18901245777/ yaisu@aliyun.com

- Next:Acceptance Detector